PTFE Polytetrafluorethylene Membrane Filter

PTFE is one of the most heat-stable plastic materials. At a constant temperature of 250°, maintaining initial characteristics without showing any breakdown. This is the type of membrane most widely used in the preparation of samples for HPLC analysis.

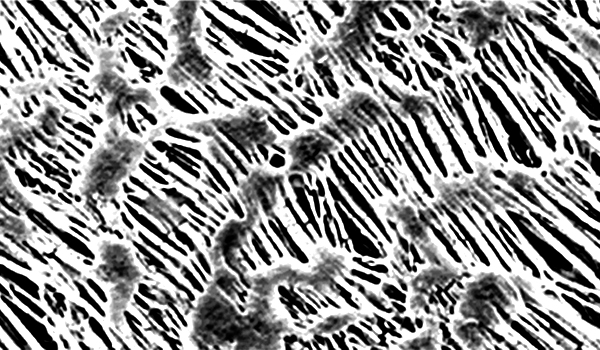

Manufactured using a (PTFE) DORSAN® Polytetrafluorethylene polymer, it obtains a chemically stable and inert microporous film. Manufactured on a polyester spun bound calendered base which provides it with high resistance to pressure and breakage. This type of membrane has a wide range of applications, both in the natural hydrophobic version as well as the treated hydrophilic version. Widely used due to their great resistance to the majority of acid, alkaline and solvent products.

FEATURES

Hydrophobic or hydrophilic versions.

Resistant to the majority of acids and alkalines.

Chemically stable and inert.

Hard wearing during handling.

Possibility of sterilisation in auto key.

APPLICATIONS

Solvent clarification

HPLC samples preparation

Corrosive products filtration

Ventilation

Microelectronics

POLYTETRAFLUORETHYLENE PTFE MEMBRANE FILTER TECHNICAL CHARACTERISTICS

| Diameter | Hydrophobic Ptfe | Pore | |

|---|---|---|---|

| M0 | 13 | PTFE | 0.20 |

| 25 | 0.45 | ||

| 47 | PTFE Hydrophilic | 1.2 | |

| 90 | 3.0 | ||

| 142 | 5.0 | ||

| 3.0 | |||

| 5.0 |

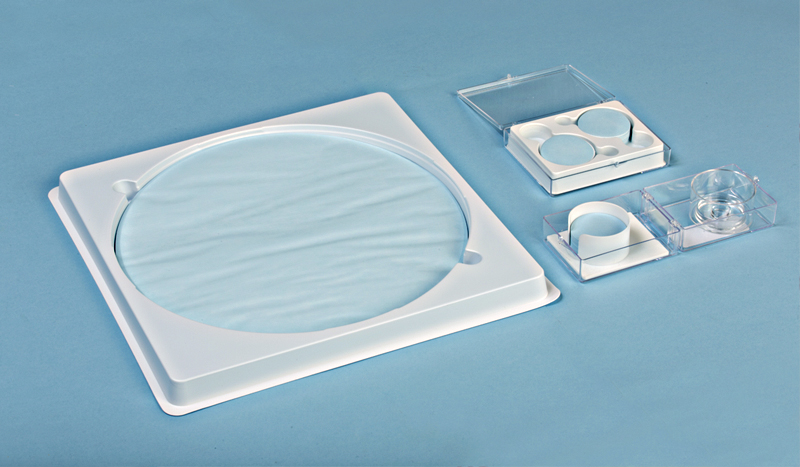

SPECIFICATIONS OF PTFE POLYTETRAFLUORETHYLENE MEMBRANE FILTER AND PACKAGING

| Diameter | Pore | Units Box |

|---|---|---|

| 13 mm | All porosities | 100 |

| 25 mm | All porosities | 100 |

| 47 mm | All porosities | 100 |

| 90 mm | All porosities | 25 |

| 142 mm | All porosities | 25 |

DOWNLOAD PDF TECHNICAL SHEET

Note. We reserve the right to modify the information contained in this pamphlet without prior notice.